Home>>Solutions>>Water & Wastewater Treatment System

Membrane Technologies

Industrial RO Plant

Aquamech's RO plants remove dissolved salts for high-quality industrial water. Our Industrial RO Plants and Chemical Sanitizable RO Plants are engineered to ensure reliable and cost-effective operation.

Ultrafiltration System

Aquamech's Ultrafiltration(UF) unit removes contaminants like SDI(Slit Density Index) , colloidals, bacteria, and viruses using low-pressure and Hollow Fiber membranes. It ensures high-quality water for downstream processes.

Benefits

- Improved RO Efficiency: Feeding water with SDI 3 or less enhances the efficiency of Reverse Osmosis (RO) units by increasing flow per square meter of membrane area (GFD).

- Fouling: Ultrafiltration removes colloidal silica and micron suspended solids from RO feed water, thereby minimizing fouling of RO membranes by particulates and other suspended impurities.

Operation

The UF system typically operates at 90% recovery with periodic backwashing for cleaning. Additionally, chemical-enhanced backwash using chemicals such as Hydrochloric Acid, Sodium Hydroxide. and Sodium Hypochlorite ensures thorough cleaning of the UF system.

Chemical Sanitizable RO Plant:

We need to remove free chlorine and other oxidizing agents from water before it enters the RO membranes. This system helps maintain membrane integrity and extends the lifespan of the RO system.

Other Recommended Post-Treatment dosings:

1. SMBS Dosing: Neutralizes chlorine with Sodium Metabisulfite (SMBS) to prevent membrane damage. Our SMBS dosing unit includes a Dosing Pump, Solution Tank, and standard accessories for efficient dosing.

2. PH Correction: PH Correction is done in combination with Antiscalant to ensure there is no scale build up.

3. Antiscalant Dosing: Controls scaling from hardness and silica for membrane protection. It comprises a Dosing Pump and Solution Tank for effective scaling inhibition.

Wastewater Treatment

Aquamech offers complete wastewater treatment (ETP - Effluent Treatment Plant, STP - Sewage Treatment Plant, ZLD - Zero Liquid Discharge) for industrial & domestic areas, meeting reuse standards. Our custom-designed solutions effectively treat any wastewater type.

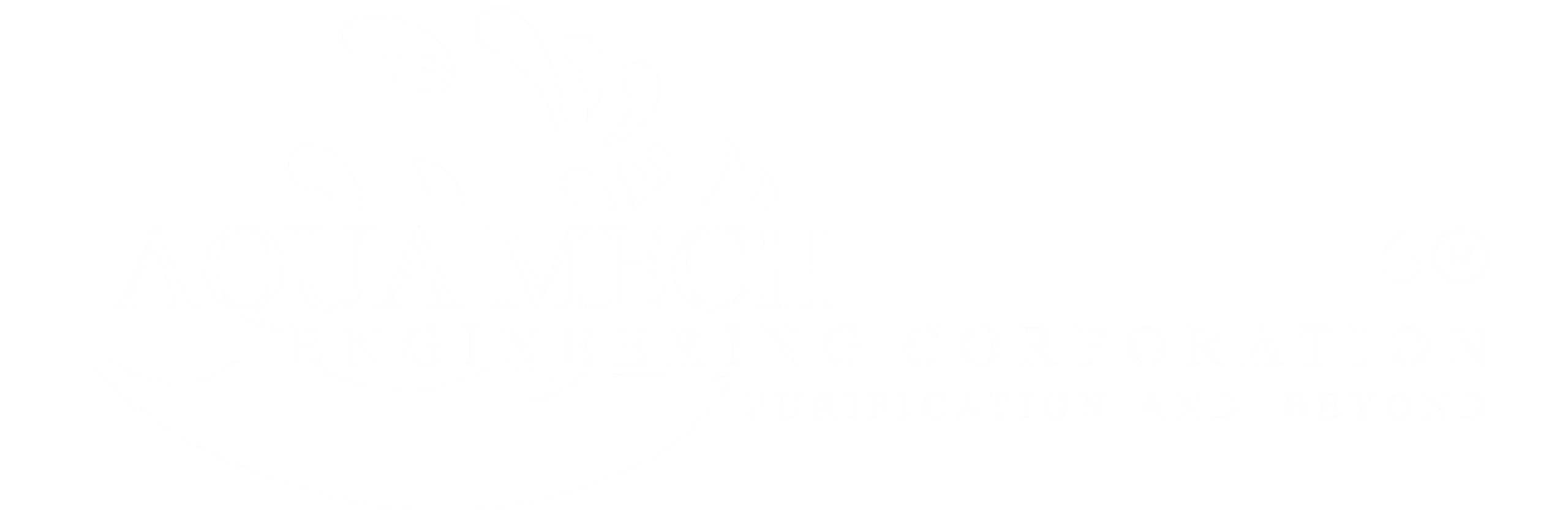

ETP (Effluent Treatment Plant) & ZLD ( Zero Liquid Discharge)

Treats industrial wastewater with custom processes based on influent conditions. Stages include:

- Primary: Removal of large solids, oil, and physio chemical reactions to precipitate some impurities.

- Secondary: Aerobic or anaerobic biological treatment.

- Clarification: Clarifiers are used for partial sludge recirculation and disposal after aeration tanks.

- Tertiary & Recycle (ZLD): Maximum water recovery through 2 stage to 4 stage RO system and recycle the water back. The final concentrate is then fed to the MVRE or MEE followed by AFTD or centrifuge to crystallise in solids.

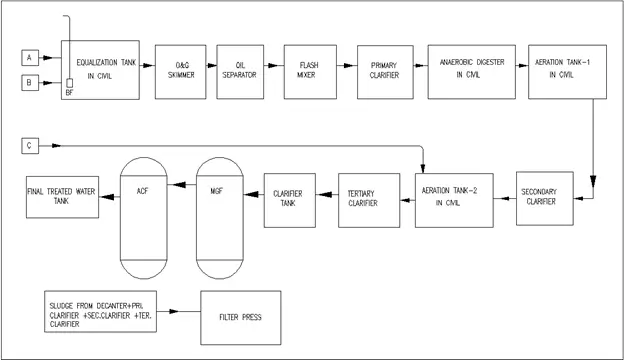

STP (Sewage Treatment Plant)

Treats domestic wastewater using efficient technologies like:

- Media Based Bioreactor (MBBR): Compact, single-tank design with low footprint and operating costs.

- Sequential Batch Reactor (SBR): Cyclic system with consistent high-quality effluent.

- Membrane Based Bioreactor (MBR): Advanced membranes for high efficiency (lower energy, smaller footprint)

Aquamech can provide solutions for complete primary secondary, tertiary, recycle and then ultimately Zero Liquid Discharge.

contact us

Get In Touch

Aquamech's resin bed technologies ensure reliable and cost-effective demineralization of water, meeting the stringent purity requirements of various industries.