Home>>Solutions

High Purity Water System

Design and installation of high purity water systems for critical applications including Hospitals, Biotech, Pharmaceutical, and Food & Beverage facilities. Guarantee compliance and reliability for critical applications in Pharmaceutical and Hygiene industries.

Aquamech High Purity Water System: Delivering Excellence In Pharmaceuticals

Design, manufacture, and install custom systems for critical processes in Pharmaceuticals, Biotechnology, Semiconductor manufacturing, and Power generation.

Our systems guarantee exceptional water quality for Purified Water, Water for Injection and Ultrapure water for Semiconductor and Laboratory applications, making us your trusted partner for Hi-Purity Water Systems

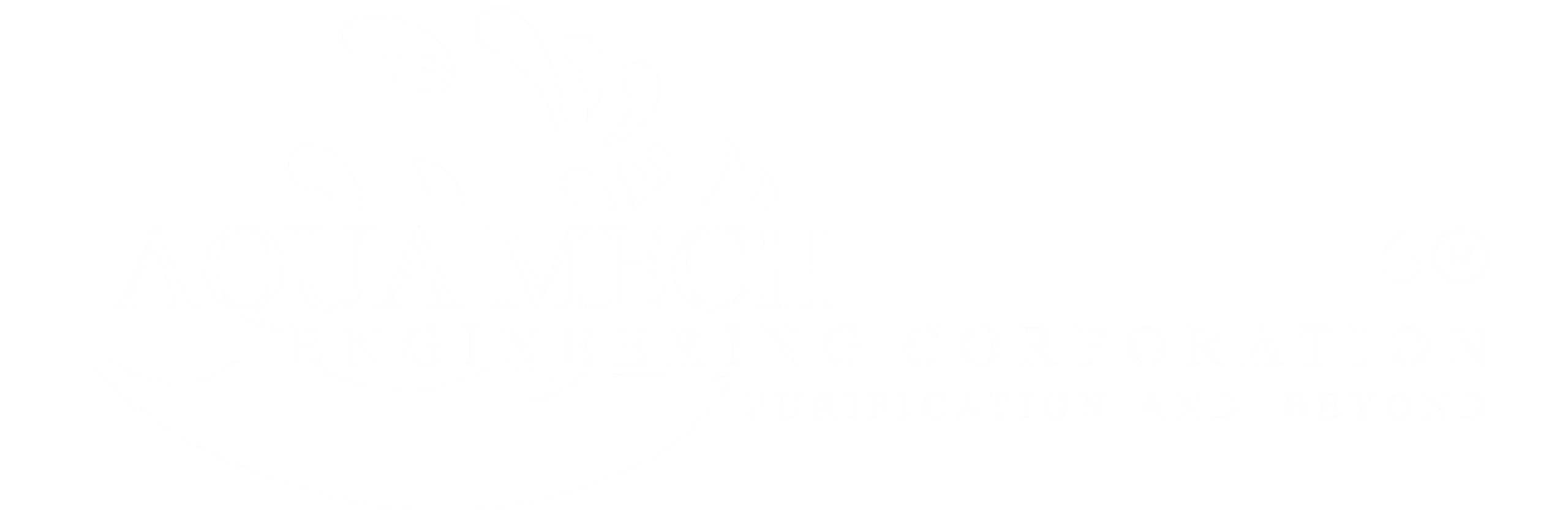

- Aquamech Hi-Purity Systems offers comprehensive water solutions for Pharmaceutical manufacturing.

- Our systems meet the strictest requirements, ensuring purity, reliability, and regulatory compliance.

- We are committed to providing innovative solutions to meet the unique needs of the pharmaceutical industry.

Purified Water & Water for Injection Generation Systems

Purified Water/ Water for Injection storage and tanks / Distributions skid

Process Skids And Clean Utility Piping

People trust Aquamech products and services

A team of highly skilled engineers, prepared to meet any request of product design, fabrication, production and project execution.

Frequently Asked Questions

A high-purity water system is designed to produce water that meets strict standards for contaminants, often required in industries like pharmaceuticals, biotechnology, and electronics. It ensures product integrity, safety, and compliance with industry regulations such as USP, EP, and WHO-GMP.

Aquamech provides high-purity water systems tailored for pharmaceutical manufacturing, bio, s, cosmetics, semiconductors, and food & beverage sectors, where water quality is critical to process hygiene and product quality.

Yes, Aquamech specializes in designing, engineering, and installing turnkey high-purity water systems tailored to specific regulatory and operational requirements. Systems include pre-treatment, RO, EDI, UV, UF, and storage with automated controls.

Aquamech designs high-purity systems in compliance with USP, EP, IS standards, and cGMP guidelines, incorporating real-time monitoring, automated sanitization, and robust documentation for audit readiness.

Aquamech is a leading engineering company providing comprehensive solutions in:

- Water & WastewatZLer Treatment

- Zero Liquid Discharge (ZLD)

- Waste Resource Recovery Facilities

- High-Purity Water Systems

- Walk-in Cold Rooms & Warehouses

- Drainage & Separation Technologies

With over three decades of experience, Aquamech delivers innovation, efficiency, and compliance in every project.

In India, industries must comply with several environmental regulations to ensure proper wastewater treatment and discharge. Key requirements include:

• CPCB & SPCB Guidelines: Industries must follow standards set by the Central and State Pollution Control Boards under the Water (Prevention and Control of Pollution) Act, 1974, and Environment (Protection) Rules, 1986.

• Consent to Establish (CTE) & Consent to Operate (CTO): Mandatory permissions from the State Pollution Control Board before setting up and operating treatment facilities.

• Zero Liquid Discharge (ZLD): Certain sectors, such as textiles and pharmaceuticals, are required to adopt ZLD systems to ensure no untreated water is discharged.

• Effluent Quality Monitoring: Parameters like BOD, COD, TDS, pH, and oil & grease must meet discharge norms. In many cases, Online Continuous Effluent Monitoring Systems (OCEMS) are required.

• Hazardous Waste Rules: Sludge and by-products from treatment plants must be handled according to the Hazardous Waste Management Rules, 2016.

• Environmental Clearance: Large-scale projects require an Environmental Impact Assessment (EIA) with a detailed wastewater management plan.

Aquamech provides fully compliant, turnkey wastewater treatment solutions tailored to meet all regulatory and documentation standards.

Aquamech’s high-purity water systems are engineered to meet the strict hygiene requirements of the pharmaceutical and life sciences sectors. From concept to commissioning, their solutions help maintain sterility, ensure process validation, and reduce contamination risks.

Absolutely. Aquamech supports DQ, IQ, OQ, and PQ documentation for validation, ensuring that your high-purity water system meets global regulatory demands.

Key technologies include Reverse Osmosis (RO), Electro-Deionization (EDI), Ultra-Filtration (UF), UV disinfection, ozone systems, loop distribution with SS316L piping, and PLC/SCADA automation for complete system control.

Yes, Aquamech provides assessment, retrofitting, and upgrading services for existing systems to improve efficiency, meet newer compliance standards, and extend equipment life cycles.

You can contact Aquamech through their official website or visit the Hi-Purity Water Systems page to request a consultation. Their technical experts will guide you through the needs assessment, design, and deployment of a custom water treatment solution.