Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Wastewater management is vital for environmental health, with grease separators playing a key role in this process. Understanding the definition, importance, and broader context of wastewater treatment is essential in navigating the complexities of maintaining water system health.

Grease separators, also known as grease traps or interceptors, are devices designed to collect fats, oils, and grease (FOG) from wastewater before it enters the main sewer system.

They prevent the flow of these substances into municipal sewage, averting blockages and environmental hazards. Regardless of size, their purpose is consistent: capturing and isolating grease from wastewater.

Grease separators are crucial in managing wastewater. Without proper interception, fats, oils, and grease can solidify in the sewer system, causing damage to pipes and infrastructure.

Moreover, untreated FOG can hinder the efficiency of wastewater treatment plants, compromising treatment processes and risking the release of pollutants into natural water bodies.

Wastewater treatment involves removing contaminants from sewage before releasing them into the environment. The process utilizes physical, chemical, and biological treatments. Grease separators play a crucial role in the initial stages by preventing grease from entering treatment facilities.

This ensures optimal functioning of subsequent processes, contributing to effective and environmentally friendly wastewater management. In the following sections, we’ll explore grease separators in more detail, examining their applications and broader implications for both treatment facilities and the environment.

1. Commercial Kitchens and Restaurants:

2. Food Processing Facilities:

3. Industrial Settings:

4. Car Wash Facilities:

5. Other Grease-Prone Areas:

The repercussions of allowing wastewater containing grease to permeate the municipal sewer system are multifaceted and severe.

Not only does it obstruct pipes, but it also facilitates the formation of corrosion, emits noxious odors, and exerts a detrimental influence on treatment plants.

Acknowledging these potential consequences underscores the critical role of grease separators as guardians of wastewater quality and infrastructure integrity.

Industries generating wastewater are mandated to implement suitable pre-treatment facilities to prevent the discharge of substances and liquids that emit noxious fumes, produce nuisance odors, harm building materials and drainage systems, or disrupt normal operations into public pipes.

In facilities where wastewater with grease accumulates, it is imperative to install grease traps compliant with EN 1825/DIN 4040-100 standards.

This ensures the effective retention of organic greases and oils present in the wastewater, particularly relevant in settings such as kitchens and meat processing plants.

Following the installation of each grease separator positioned below the backflow level (typically street level), a double lifting plant or complete pumping station must be provided.

The varied specifications for grease separators, lifting plants, and complete pumping stations necessitate adjustable products available in different sizes and materials.

For decades, Aquamech in collaboration with ACO has offered an extensive product range encompassing grease separators, lifting plants, and complete pumping stations designed for both ground and free-standing installations.

All grease separators manufactured by ACO Haustechnik and provided by Aquamech adhere to the relevant standards, namely EN 1825 and DIN 4040-100.

The listed grease separators in the product range undergo hydraulic testing and possess general official approval, including the new application permit from DIBt Berlin.

Furthermore, the separator systems undergo routine inspections by Landesgewerbeanstalt Bayern to ensure compliance with the currently applicable test standards, thus affirming the quality and reliability of the production process.

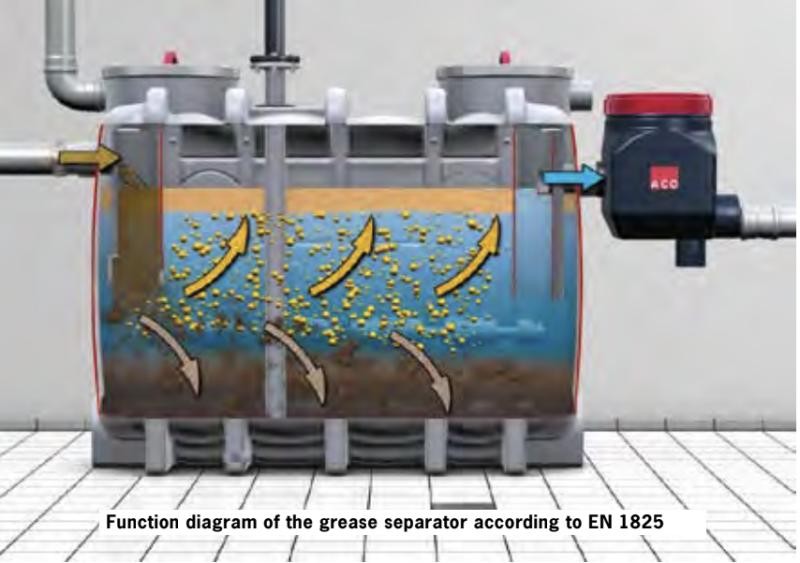

Grease separators operate on the fundamental principle of gravity separation, utilizing the density difference between various components in wastewater.

The process involves the gravitational settling of heavier wastewater components to the bottom, while lighter materials such as animal oils and fats rise to the top within the separator.

The sediments collected in the sludge trap and the grease layer undergo a specialized cleaning process.

A high-pressure jet, generated by a special orbital cleaning head at pressures of up to 175 bar, selectively destroys the sediments. This process homogenizes the contents of the separator, making them suitable for pumping.

Depending on the installation site’s location, the contents of the separator can be efficiently pumped for disposal. An on-site permanently installed line facilitates the transfer of the separator content to a disposal vehicle.

Alternatively, an optional disposal pump can be employed for transporting the content to the disposal vehicle. This flexibility ensures an effective and convenient disposal process, contributing to the overall efficiency of grease separator systems.

Grease separators, crucial in preventing the adverse impact of fats, oils, and grease (FOG) in wastewater systems, come in various types designed to address specific needs and volumes.

Understanding these types is essential for selecting the most appropriate solution based on the scale and requirements of the operation.

2. Hydraulic Grease Separators:

3. Automatic Grease Interceptors:

4. High-Capacity Grease Separators:

5. Passive Grease Traps:

6. Mechanical Grease Interceptors:

7. Below-Ground Grease Separators:

Overview: Installed underground, these separators save space and are discreet while efficiently handling grease removal.

Applications: Ideal for locations with limited surface space, such as urban areas and densely populated commercial districts.

Understanding the specific features and applications of each type of grease separator is crucial for implementing an effective and tailored solution in diverse settings.

In the subsequent sections, we’ll explore the benefits of using grease separators, guidelines for their installation, and the importance of routine maintenance to ensure optimal functionality.

The dimensioning specifications for a grease separator without a partition between the sludge trap and separator chamber are outlined as follows:

The dimensioning methodologies by EN 1825-2 or DIN V 4040-2 are categorized based on specific criteria for different applications:

2. For Meat Processing Plants:

It is important to note that these dimensioning approaches consider factors such as simultaneity factors and operating hours, ensuring a comprehensive and accurate assessment of the requirements for each specific context.

In this phase of the partial disposal process, the cone part is subjected to controlled heating. The objective is to elevate the temperature sufficiently to melt and liquefy accumulated grease effectively. This thermal treatment ensures the grease’s transition into a more manageable state for subsequent collection.

2. Collection of Grease and Sludge:

Following the heating phase, the melted grease and sludge are meticulously collected in separate barrels. This separation is crucial not only for ease of handling but also for facilitating distinct disposal pathways for these materials. The collected grease represents a valuable resource that can undergo further processing or recycling, contributing to sustainability goals.

3. Barrel Replacement:

Scheduled barrel replacement is a fundamental aspect of this process. Depending on the rate of grease accumulation, barrels are systematically replaced, ensuring that the system operates efficiently and without disruptions. This regular maintenance activity is integral to the sustained effectiveness of the partial disposal system.

The systematic separation of grease and sludge into dedicated barrels is a key feature of the partial disposal system. This separation not only aids in efficient waste management but also allows for targeted processing or disposal methods based on the nature of the materials.

2. Odor-Free Extraction:

An important consideration in the partial disposal process is the extraction of sludge and grease without causing any odor nuisance. Advanced technologies or design features are often implemented to ensure that this extraction occurs in a manner that is not disruptive or unpleasant for the surrounding environment.

3. Scheduled Barrel Replacement:

The regular replacement of barrels is a planned and integral aspect of the system. This scheduled maintenance is designed to accommodate the varying rates of grease accumulation, preventing overflows or system inefficiencies. It also contributes to the overall reliability and longevity of the disposal process.

4. Continuous Kitchen Operation:

An advantageous feature of this partial disposal method is its seamless integration with kitchen operations. Disposal activities are designed to occur without causing interruptions to the regular functioning of the kitchen. This ensures a continuous workflow without compromising on hygiene or efficiency.

5. No Need for Disposal Truck:

An environmentally friendly aspect of this process is the elimination of the need for a disposal truck. This not only reduces operational costs but also minimizes the carbon footprint associated with traditional disposal methods. The absence of a disposal truck enhances the overall sustainability of the partial disposal system.

There are two installation situations for grease separators: Freestanding grease separators and grease separators for underground installation. A precondition for easy disposal, maintenance, and cleaning of the grease separator is a readily accessible installation location.

In addition, always verify that the pipe between the accumulation point and the grease-containing wastewater and the grease separator is kept as short as possible. Furthermore, the installation may not be done in stagnant rooms traffic, or storage areas.

The setup may not be made in the vicinity of living quarters. The most important criteria that must be considered when choosing between a free-standing or underground installation are discussed in the following.

The connection between the access road, installation, and design:

The access routes to the installation room must also be observed in the free-standing installation. To select the proper separator, which can also be installed via stairways, winding corridors, or light wells, the conditions on-site must be known. Various designs allow an installation as needed.

Aquamech offers top-notch grease separators, lifting plants, and pumping stations, ensuring not just compliance but top-tier performance.

Opting for Aquamech means more than getting equipment; it means teaming up with a partner dedicated to environmental care. Their products, suitable for various setups, meet the highest standards for reliability and effectiveness.

Whether you’re in food service, industry, or any sector dealing with grease-heavy wastewater, Aquamech has personalized solutions.

From installation tips to routine upkeep, Aquamech supports your journey toward a future where wastewater management aligns seamlessly with environmental responsibility.

Feel free to contact our Design Head – Navdeep Singh Sethi or contact us at sales@aquamech.co.in.